| Flow

101 - Smooooth Transitions |

|

When

it comes to good flow, one of the most important things is smooth

transitions. When you hear “port and polish” used in describing

engine modifications it does not always mean making the ports of the

head or manifolds larger, but it does always mean making them all

match up and smooth. Whether it is your head and manifolds, or a simple

low-buck cold air intake system with a cone airfilter it is important

to think about the best possible way to aid airflow. |

|

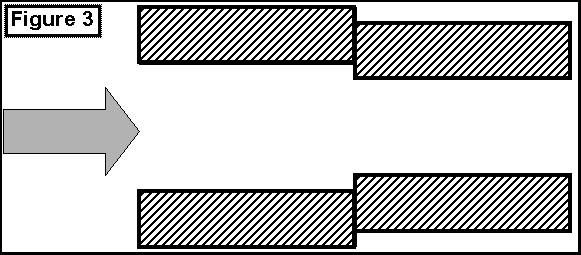

Smooth Inlets and Outlets Figure 1 shows a cross-section of pipe, manifold runner, etc. The arrow shows the direction of airflow through the section of pipe. The pipe has the typically found hard or sharp edged inlet and outlet. Since this is the “101” course, we will not get into terms such as “boundary layer” but we will just say that the corners disrupt airflow as the air enters and exits the sections. |

|

|

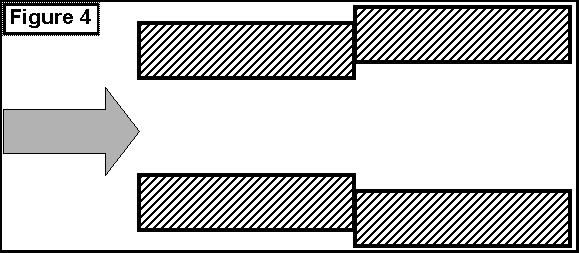

Figure 2 shows the same cross-section of pipe with

the inlet and outlet radiused (or filleted) to remove those edges that

disrupt the airflow. Any radius is better than no radius, however, the

theoretical best is where the radius “R” of pipe is also

the radius of the “fillet” (radius) on the inlet/outlet

of the pipe. |

|

|

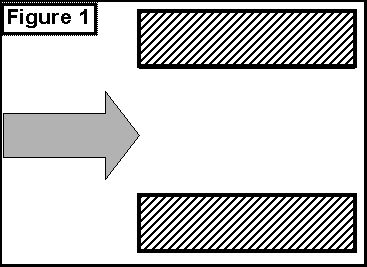

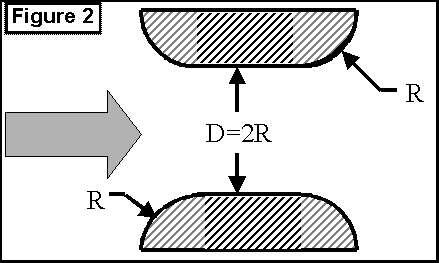

Transitions - Increase vs. Decrease Whenever possible, when making transitions, try not to decrease the diameter of the pipe/runner as shown in Figure 3. The best flow is to keep the same size, however you can increase the diameter as needed Figure 4. |

|

|

|

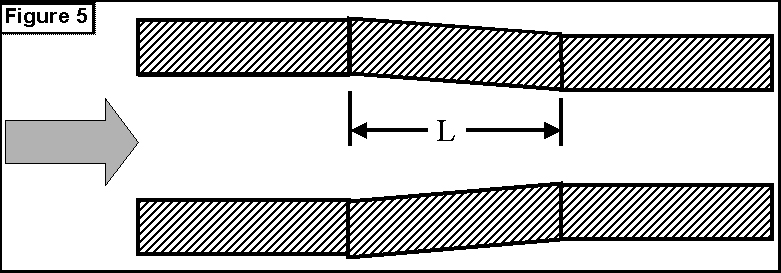

Transitions - Cross-Section Reductions Although we should not try to reduce cross section whenever possible, sometimes we have to, like when we have a cone airfilter that fits on a 3” pipe and a stock turbo with a 2” inlet. The best thing to do in this situation is to make sure that the transition is nice and smooth. The sharp edge in the stepdown shown in Figure 3 will certainly disrupt flow. The best practice is to make this transition like Figure 5 as gradual as possible over as long of a length “L” as possible. If this is not an option, you can also use smaller steps in pipe sizes, for example do not jump from 3” to 2”, however, make a transition pipe out of a few different sizes in between such as 2.75”, 2.5” then 2.25”. At a minimum, make sure the edges are either radiused like in Figure 2 or at lease beveled. |

|

|

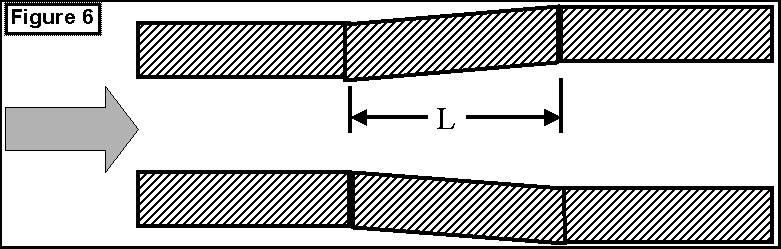

Transitions - Cross-Section Increases As with reductions, increases should be treated the same way. although the frontal edge in Figure 3 is much worse than the rearward edge shown in Figure 4, they both disrupt flow. As with decreases, increases should be made as gradual as possible over a long length “L” as shown in Figure 6 or with small steps and radiused edges as mentioned above. As with the decrease, try to step th increases gradually, for example do not go straight from the 2” turbocharger outlet to a 2.5” intercooler pipe, but rather use a 2.25” pipe in between, or make a custom one using a section of 2”, a section of 2.25”, then a section of 2.5”... you get the idea. |

|

|

Matching Ports With all of the above flow “rules of thumb” you can imagine how important port matching can be. The ports of the cylinder head and intake or exhaust manifold should be matched for the best performance. This does NOT necessarily mean gasket matched, however instead means having each item matched to each other for example the intake runner ports to the heads intake ports, and the heads exhaust ports to the exhaust manifolds inlet ports. Another good place to port match is the upper and lower halves of a 2-piece Turbo II intake manifold as they are somewhat notorious for mismatch. Gasket matching may be desired later when looking to enlarge the ports to increase their overall flow capability, however, if it is a mild setup the gasket size does not need to be reached. |

|

Polishing Smooth is good, so if you do port runners or weld pipes together, make sure that the surfaces are smooth too! |

|

Turbochargers Mask Inefficiencies! With all of this said, there is one thing going for us with our turbo cars. When you are pushing the air thru an induction system with positive pressure (boost) instead of sucking it in with vacuum (naturally aspirated), all of these flow considerations are a little less important. Maybe that is one of the contributing factors in how these Shelby Dodges make decent power with “K-Car” manufacturing costs? Maybe this is also how these cars can make even more power by simple “cleaning up” those manufacturing inefficiencies! |